Production and testing

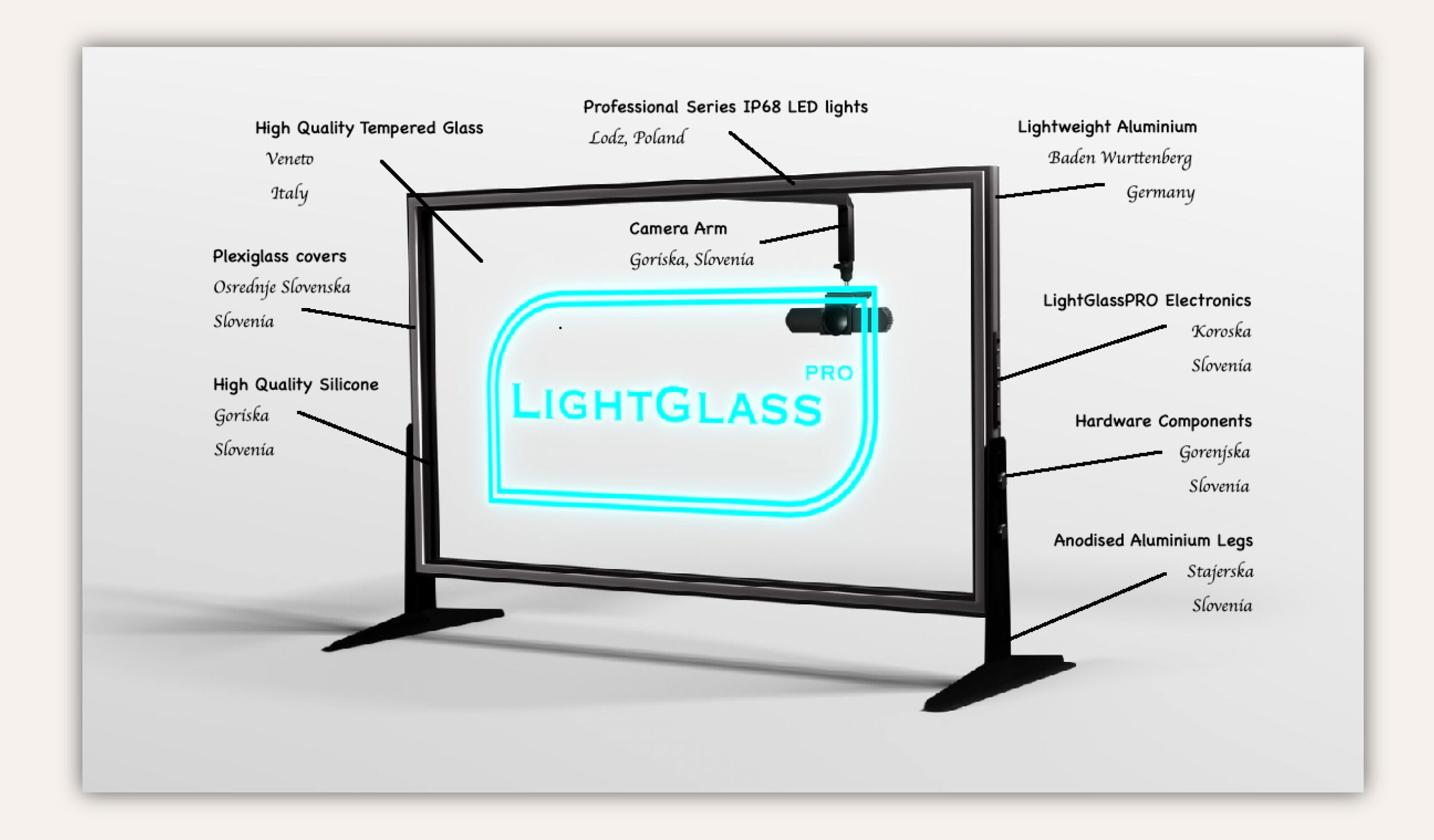

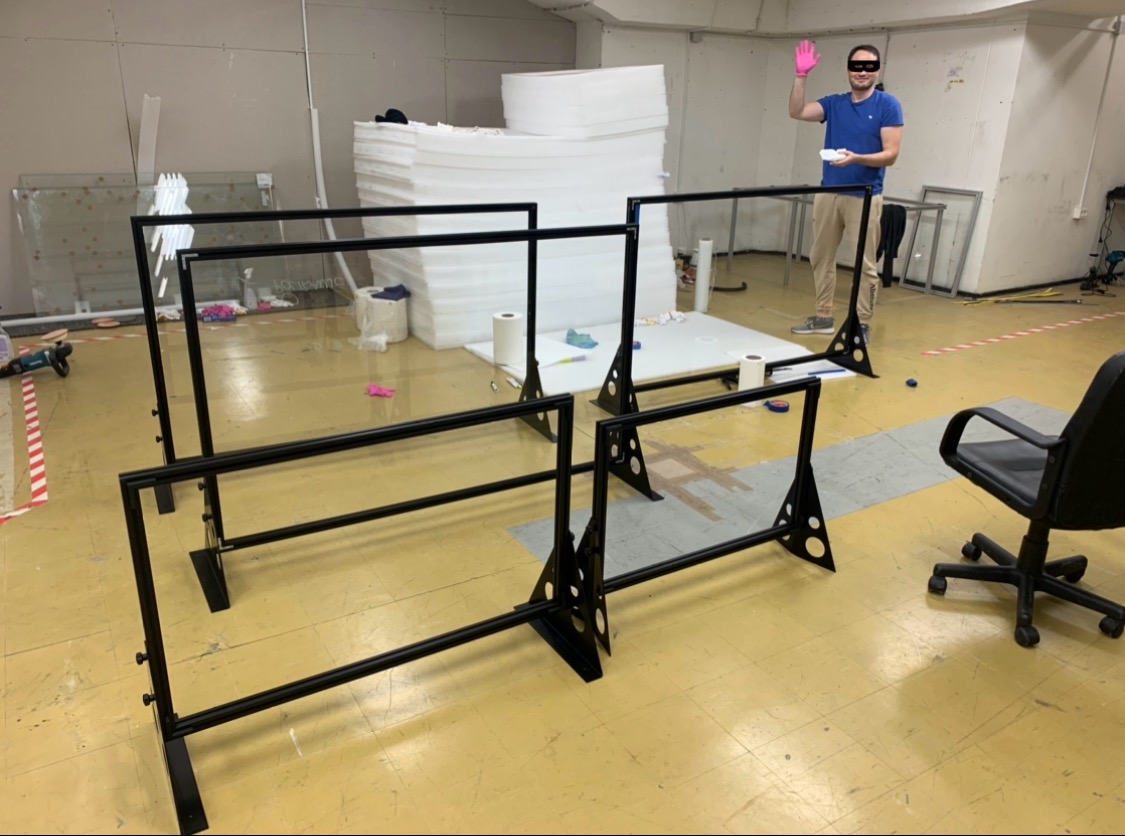

Carefully selected components from well known European manufactures are a must in order to produce quality product. After hours of sourcing, designing and testing we are proud to produce Lightboards, that will satisfy your

expectations.

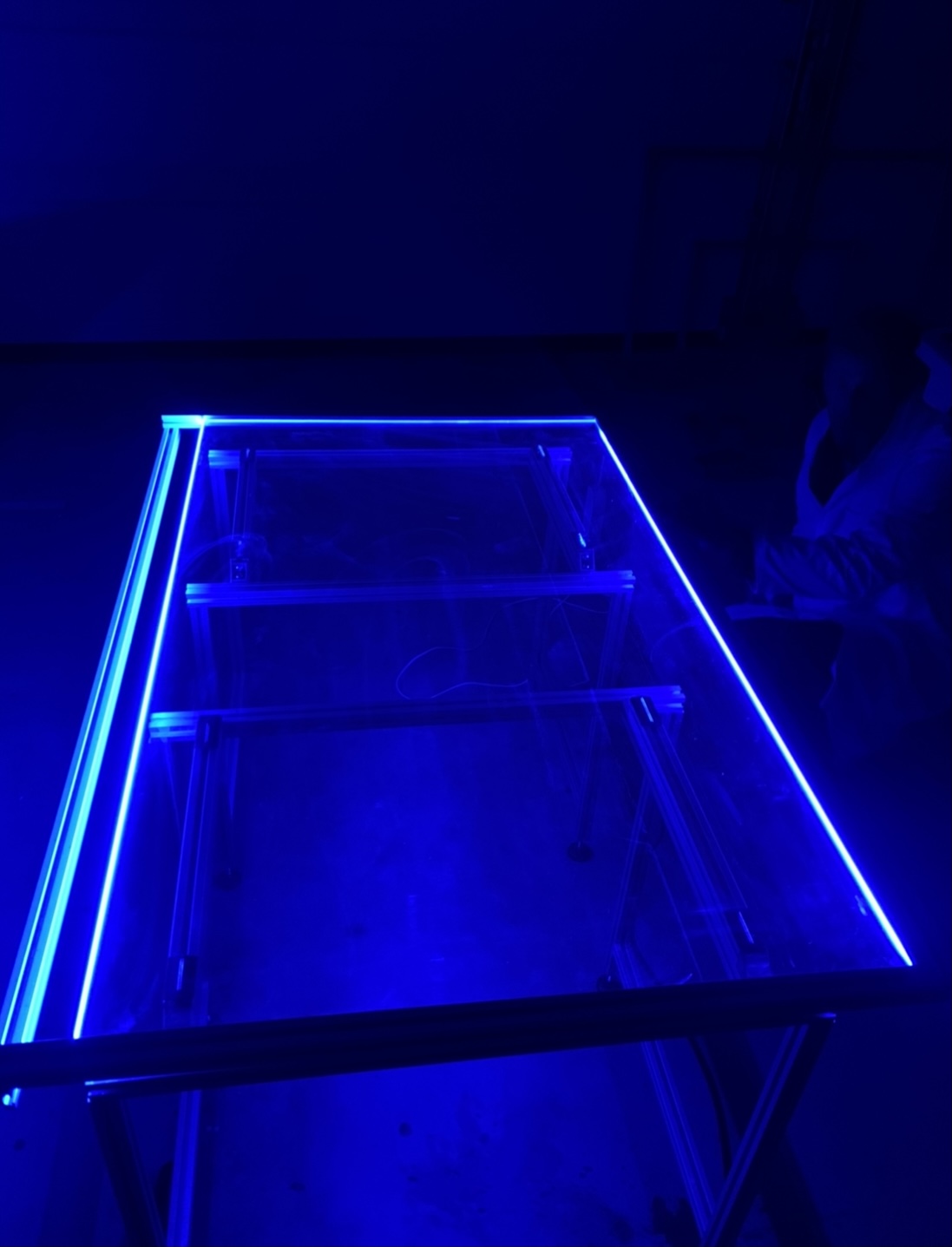

Production starts with selecting and inspecting materials, finding any imperfections and the best ways to remove them or just use new piece. Some imperfections, like air bubbles in glass, are always present, but our high standard inspection process gives us selected materials and eliminate any imperfections, that could be visible while using the product in the way it was designed for.

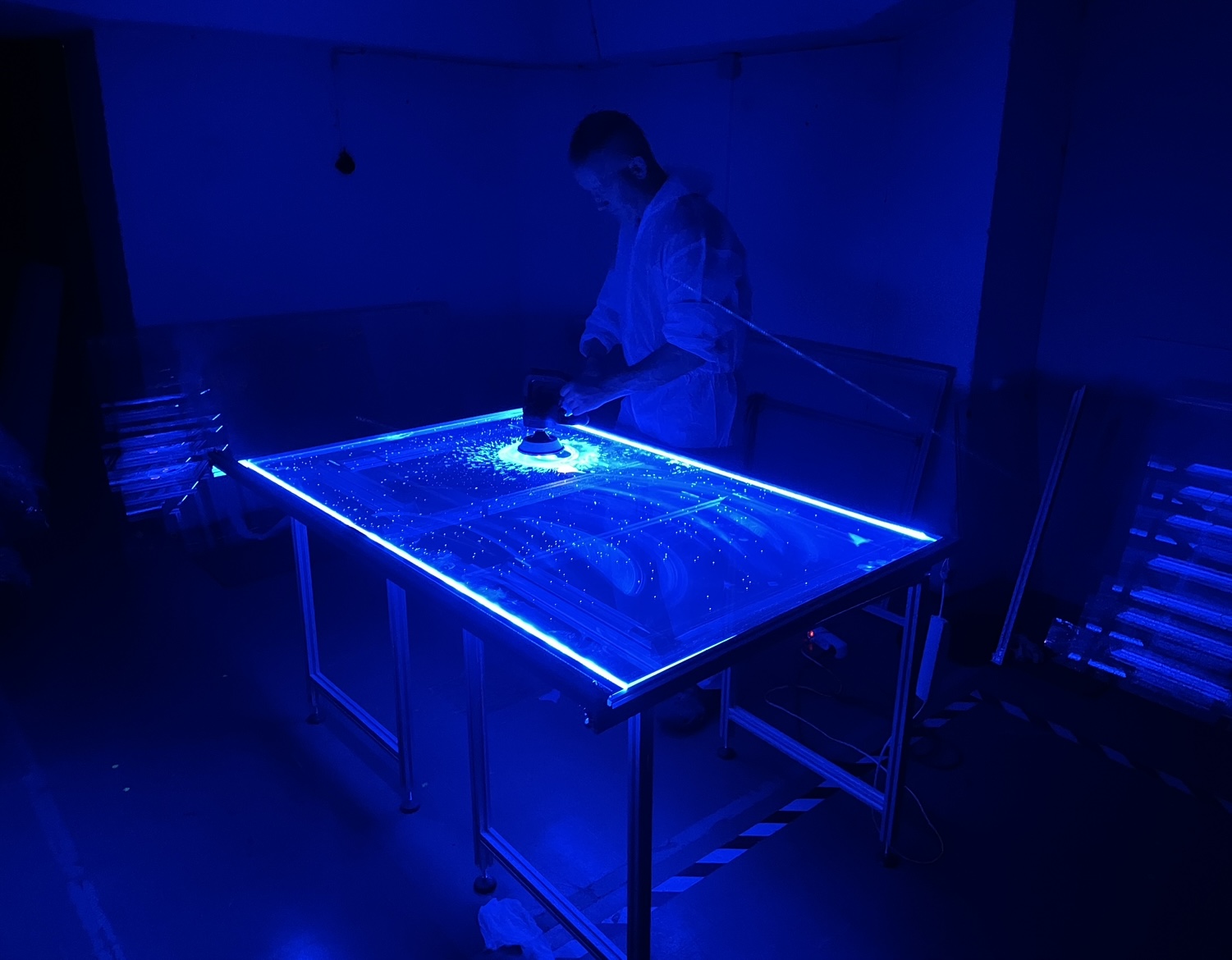

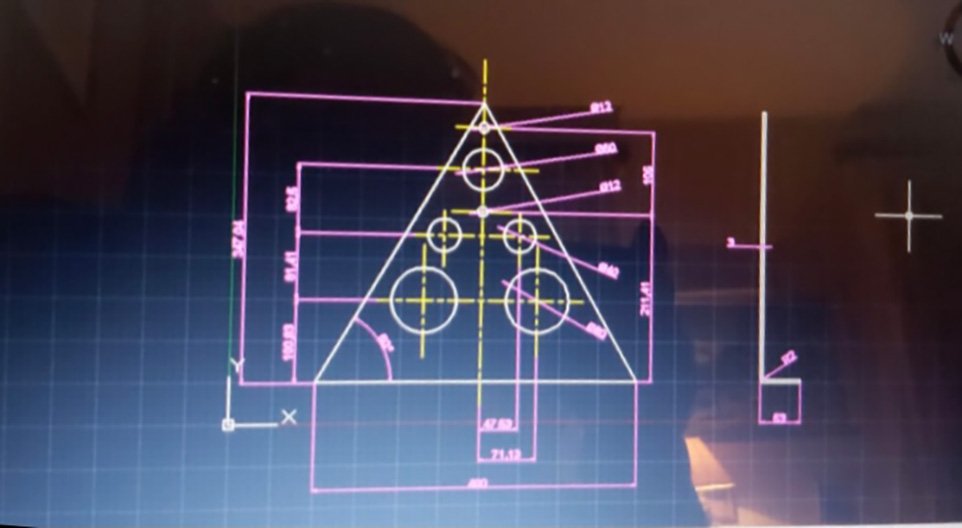

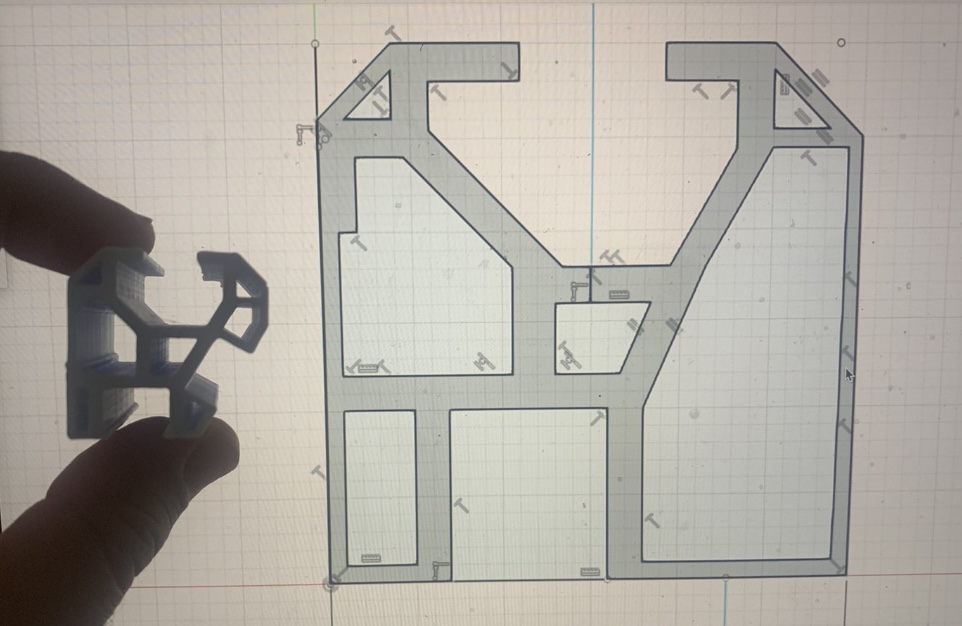

Designing components

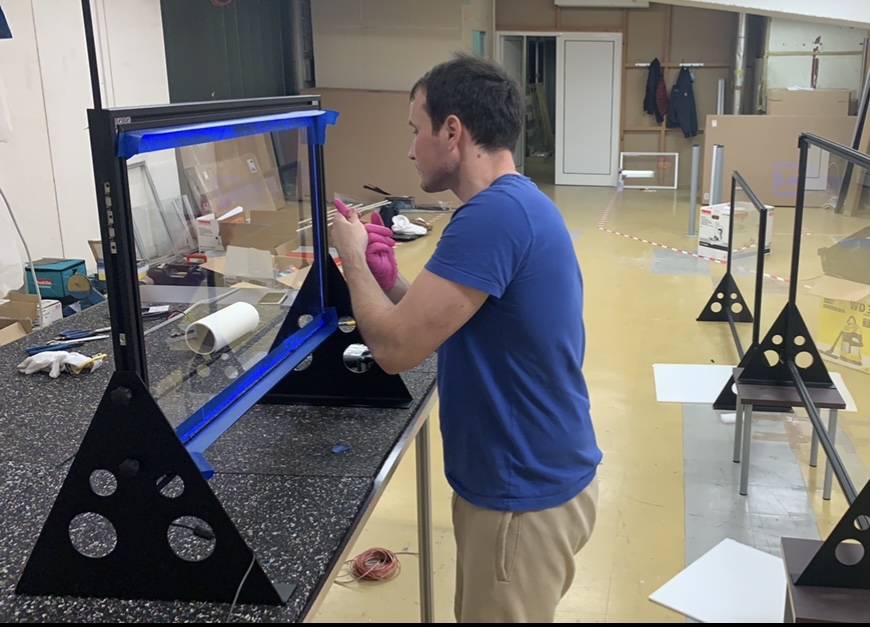

Siliconing

After cutting aluminum and assembling of all the components, next step is application of silicone.

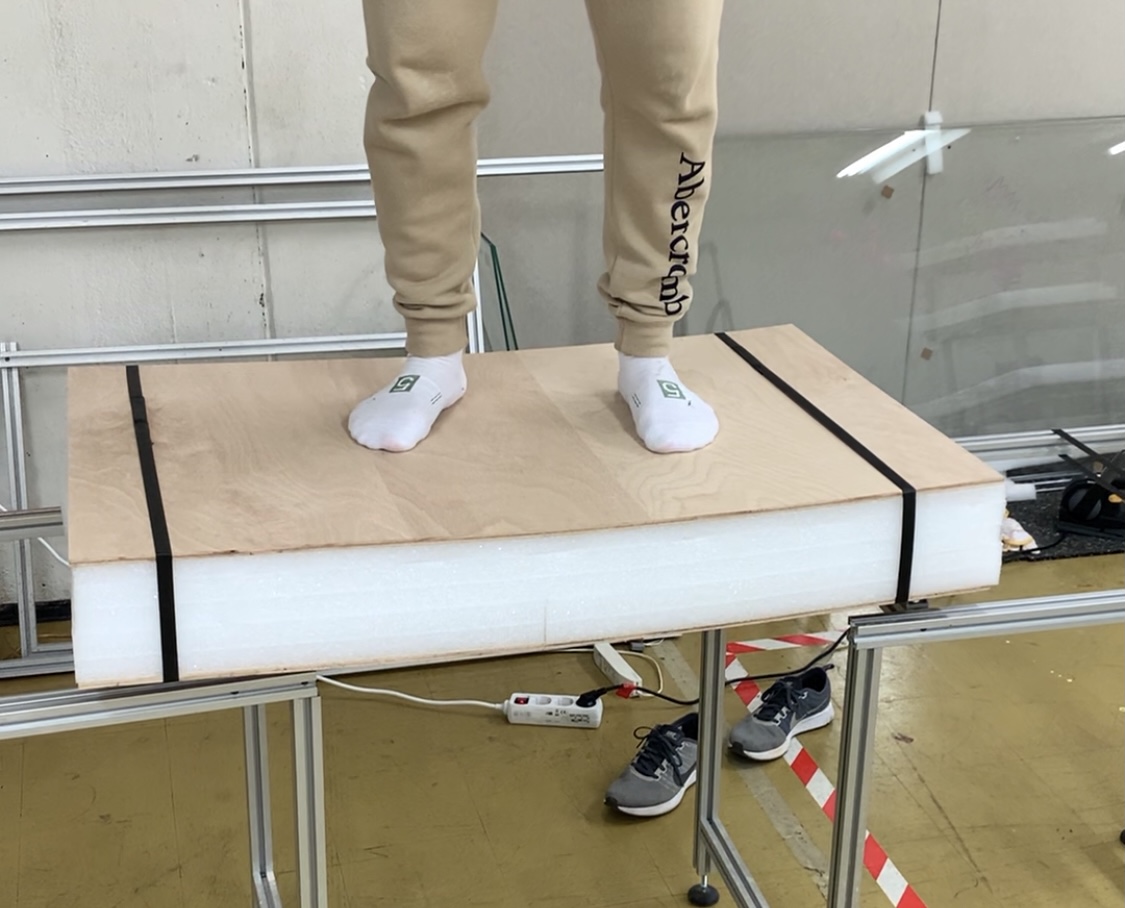

Shipping

After final inspection and cleaning product is packed for shipping. It was quite a challenge to produce packaging that would withstand shipping and arrive safely to your door.

Even after product arrives to you, DON’T THROW AWAY PACKAGING , you can use it to properly store your product and in case of portable units, to use packaging as carry case, and since it is wood you can paint it to your desire.